Getting Started with AI SCADA

AI SCADA is an AI-powered next-generation industrial SCADA platform.

What is AI SCADA

AI SCADA integrates traditional SCADA monitoring capabilities with modern AI technology to address critical challenges in high-density data acquisition, intelligent data analysis, open system integration, and AI capability fusion. It provides a future-ready industrial data intelligence platform for OEMs (Original Equipment Manufacturers), SIs (System Integrators), and end users.

Core Capabilities

AI-Driven Development

Natural language generation of views and C# scripts, improving development efficiency by 80%

- AI View Generation: Create professional interfaces in 10-30 seconds

- AI Script Generation: Convert natural language to code

- AI Smart Binding: Automatically match data to components

High-Speed Data Acquisition

100ms polling cycle, supporting 200+ industrial protocols with independent real-time control

- Support for 100,000+ high-density tags

- Siemens, Mitsubishi, Omron, FANUC, and other mainstream protocols

- Millisecond-level control command response

Intelligent Data Analytics

Trend analysis, SPC, OEE statistics, completing the "Data → Analysis → Decision → Control" loop

- Real-time trend charts and historical data comparison

- SPC quality control charts and OEE equipment efficiency statistics

- Defect analysis and traceability

Open System Architecture

RESTful API, MQTT, database connectivity for seamless integration with ERP/MES/MOM systems

- Rich standard interfaces

- Quick integration with third-party systems

- Support for C# and Vue secondary development

Comparison with Traditional SCADA

| Dimension | Traditional SCADA | AI SCADA |

|---|---|---|

| Development | Manual view design, weeks-long cycles | AI-generated views in 10-30 seconds |

| Scripting | Manual coding, error-prone | AI-generated scripts from natural language |

| Data Acquisition | Second-level polling, struggles with high density | 100ms high-speed acquisition, 100,000+ tags |

| Data Utilization | View-only, difficult to analyze | Intelligent analytics: SPC/OEE/trends |

| System Integration | Closed systems, difficult integration | Open platform, 200+ protocols, flexible |

| Development Experience | Compile-download-test cycles | Real-time editing, instant preview |

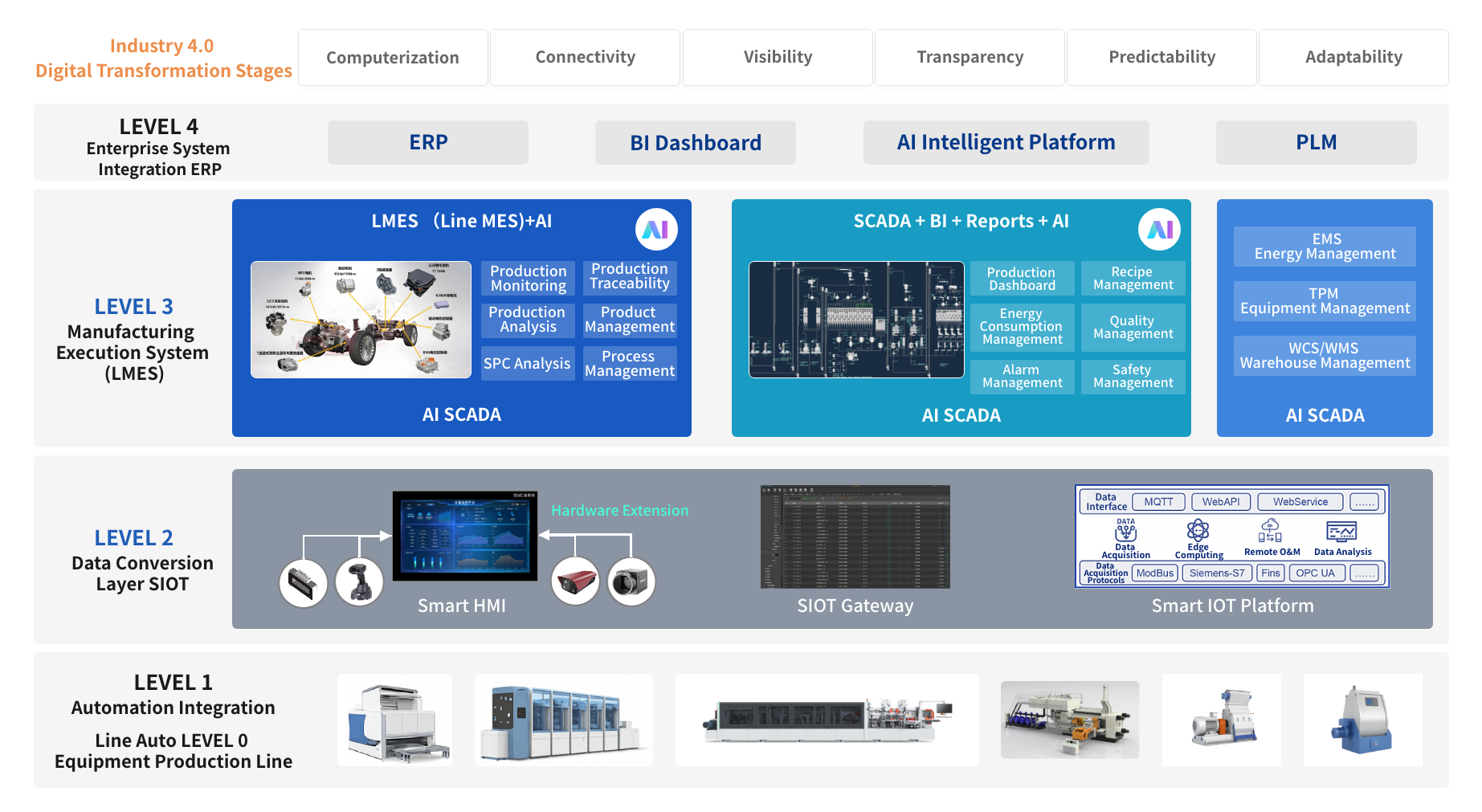

System Architecture

| Tier | Component | Purpose |

|---|---|---|

| Client | Editor | Development tool: project configuration, view design, scripting |

| Vision | Runtime environment: real-time monitoring, data viewing, operations | |

| Service | Host | Core services: project management, authentication, data processing, APIs |

| SIOT | Tag services: device communication, data acquisition, real-time control (100ms) | |

| Data | MySQL | Relational database: project configuration, user info, alarm records |

| InfluxDB | Time-series database: tag history, high-frequency time-series data |

Typical Use Cases

Third-Party System Integration

Quickly integrate with ERP, APS, MOM, MES systems without complex development, connecting end-to-end data workflows

Production Visualization and Control

Build real-time monitoring interfaces displaying equipment status and process parameters, supporting alarms, recipe downloads, and work order operations

Production Data Analysis

Analyze equipment parameters through trend curves, SPC, OEE statistics, and defect analysis to support production optimization

Equipment Control and Smart Hardware Expansion

Control assembly lines, welding stations, and other equipment while supporting smart cameras, barcode scanners, marking machines, and other hardware expansions

Get Started

Download and Install

Complete installation in 5 minutes

Run Sample Project

Quick experience in 3 minutes

Build Your Project

Create your first project from scratch